Techniques, Expertise & Capabilities

A-Line Switchboards Manufacturing Techniques

A-Line manufactures switchboards from:

- Mild steel

- Aluminum

- Zinc anneal

- Stainless Steel

A-Line’s Expertise

A-line…

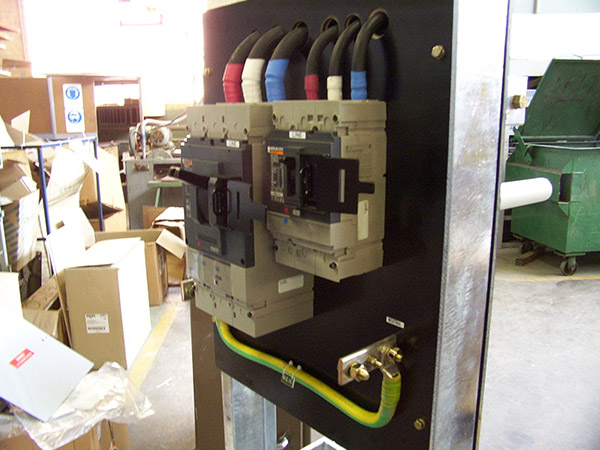

- constructs switchboards with distribution capacities up to 6500amps.

- offers purpose built switchboards to suit existing space.

- builds boards to operate under the harshest environment up to IP65 rating.

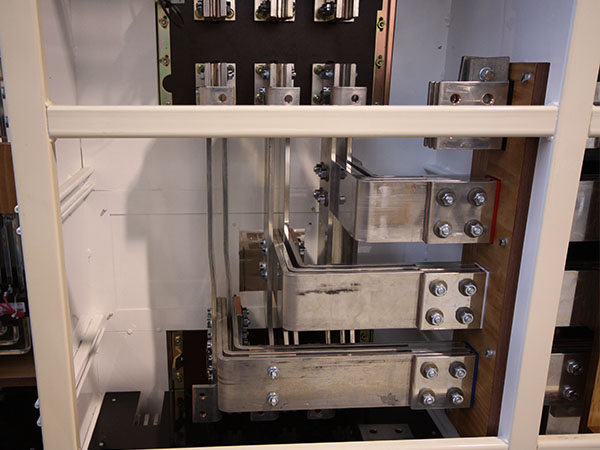

- constructs main switchboards to meet up to form 4B (AS 3439-1) segregation requirements.

- utilises tinned copper bus bar for its busway construction, giving the customer the best possible meshed join available.

- produces switchboards that are powder coated to a durable high-quality finish, meeting all Australian Standards.

- produces fully and partially type tested switchboards with fault current ratings up to 80KA for 1 sec.

On site Capabilities

A-Line has a mobile workshop that is capable of performing any on site modification, specializing in out-of-hours and weekend work. The workshop allows copper busbar up to 100mm X 10mm to be cut, drilled and bent on site, with alterations up to 3500amps being successfully and easily accomplished. It is kitted out with a 3KVA generator, lighting, fully stocked bolt rack and two full length work benches, no job is to big or complicated.

A-Line offers its clients prescribed and non-prescribed work along with supplying a certificate of “Electrical Safety” upon completion.

Pillars & Bus Bar Manufacturing

A-Line outdoor Pillars – Custom made pillars

A-Line’s outdoor pillars give our clients a cost effective solution to installing a “Supply Capacity Control Device” circuit breaker (MCCB) or air circuit breaker (ACB).

A-Line produces a fiberglass version fitted with a M.E.N link to suit your requirements from 100amps to 1250amps using MCCB’s.

A-Line also offers a solution for the 1600amp to 4000amp current range using ACB’s, utilising a variety of zinc anneal sheetmetal cubicles outdoor rated to IP65, mounted upon a hot dipped galvanised plinth constructed to your mounting requirements.

A-Line pillars are designed to meet all the requirements as outlined in the latest version of the “Service and Installation Rules”

Techniques, Expertise & Capabilities

Bus Bar Manufacturing – Standard, Non-Standard – Copper & Aluminium

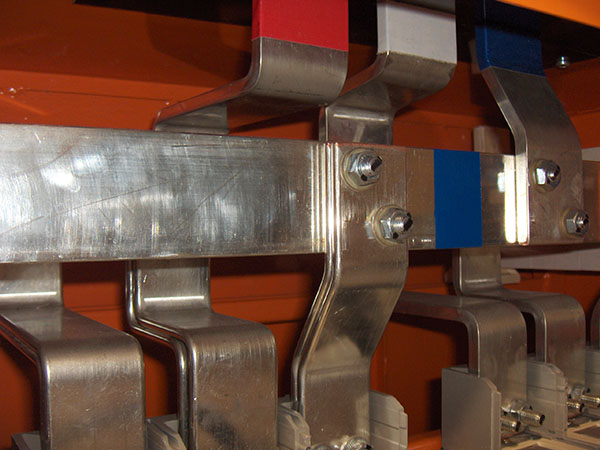

CNC BUS BAR BENDING

A-Line Switchboards have a number of CNC style machines designed to produce high volume standard Bus Bar configurations along with having the capabilities to produce complex, one-off custom fit Bus Bar Solutions.

Bus Bars can be constructed to meet all your needs up to 4m in length and all sizes.

Bus Bars can be hole punched to any pattern requirement from 5mm to 25mm.

Bus Bar Bending capabilities:

From 12mm x 3mm up to 125mm x10mm.

Need Bus Bars now?

Most orders can be processed within 24 hour period.